CANADIAN COPACKING GROUP HELPS CLIENTS GROW

For the Heming family, the lure of the Rocky Mountains, milder winters and growth potential for their business, Canadian Copacking Group Inc., was enough to prompt a wholesale move to Airdrie.

Kevin, his wife Annette, and brother Chris had been running their company out of Winnipeg since 2018, with Kevin and Annette relocating their family to Airdrie this past July. “Partly to expand operations and partly for personal and family reasons,” says Kevin. “We have a young family. Plus, we love the mountains.”

Airdrie is a great location that is geographically feasible for many of their existing clients, he says, and space is affordable. “It’s a great city for business growth.”

It’s a pretty great place to raise a family, too, which played a big part in their decision. “Our kids love Genesis Place,” says Annette. “And we only have a seven-minute drive to work, rather than 45 minutes each way in Winnipeg, giving us more time to do the things we like to do as a family.”

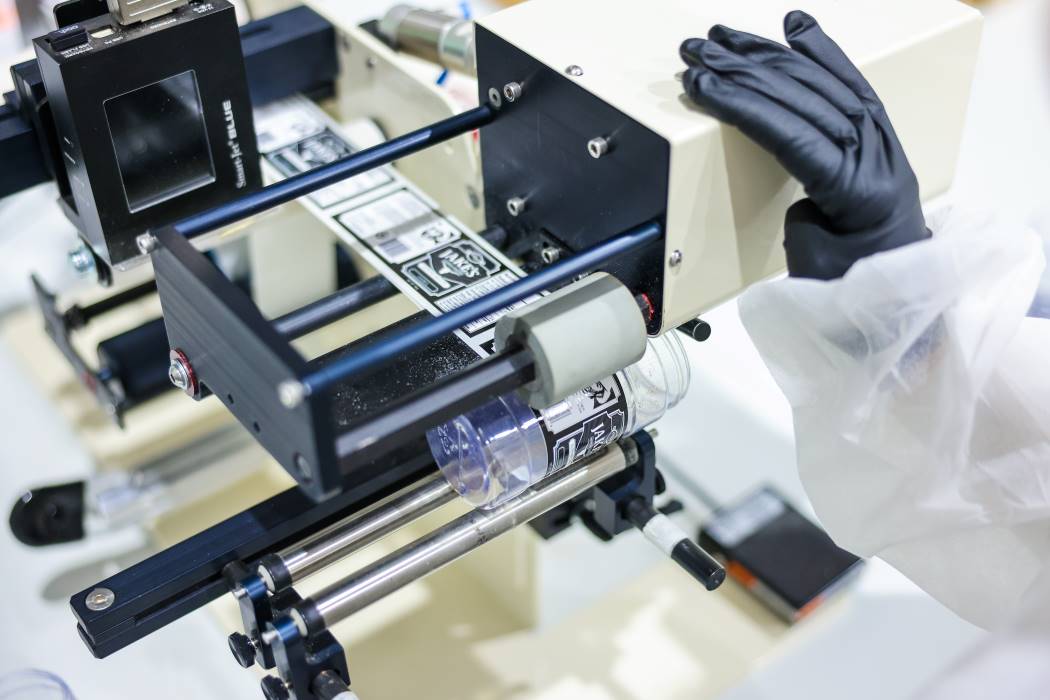

The company is also a perfect fit for the City’s increased focus on growing Airdrie’s agribusiness industry, as Canadian Copacking does both dry and liquid filling, with a focus on dry filling. For example, Jake’s Legendary Spices are packaged at the Airdrie facility, as are Wildlife Distillery’s non-alcohol liquid products.

“The business was started first and foremost to help people,” says Kevin, noting the business began as a boutique launching point for food processors that needed to graduate from commercial kitchen production into a larger volume business model, and yet still did not have the resources or strategy to open their own packaging facility.

Coming from a packaging equipment and automation background , “We saw a lot of lower volume clients that did not have the ROI to purchase equipment but still needed a path to grow.”

In other words, they could produce plenty of product but couldn’t do the packaging.

“We help clients that are growing out of the commercial kitchens, with a forecast for sales growth. We do runs with smaller quantities that allow us to be more flexible for start up companies or companies that are just about ready for explosive growth. It is also a benefit that they can expand into larger grocery chains with us, using our food safety programs.”

It’s a unique business model that’s proving to be a real win-win for both Canadian Copacking and their clientele.

“We have more flexibility in what packaging types we can still work with versus highly automated and rigid systems,” says Kevin. “We are having a great experience with local entrepreneurs. We have allowed start ups and small business to use our services are not geared towards the ‘big guys’, so our minimum order requirements are lower than most packagers.”

As for their own business, they plan to grow that too, says Heming. Current production capacity is about 3,000-4,000 units a day for dry package fills.

“We plan on growing our business past our current space in the next three to five years, as we have a lot of equipment we can still fit into our place. We are always seeking opportunities that fit.”